It is more suitable for components that want to suppress thermal deformation and high-precision bonding. The assembly of the laser pickup head, the assembly of the optical lens, the automatic alignment of parts, the fixing of coil windings and the fixing of small devices in the terminal processing medical equipment. Pure ultraviolet light output, UVATA-UP series light source emits 365nm peak monochromatic light, avoiding The cured part is affected by radiation outside of 350nm~400nm. There is no thermal radiation, and the 365nm ultraviolet band is very suitable for UV irradiation. The irradiation beam does not contain infrared rays, which reduces the temperature rise of the illuminated workpiece. It is a good application in processes that require low temperature, high precision, and low thermal deformation in bonding. Such as the assembly of optical lenses. Low power consumption, greatly saving energy compared with traditional high-pressure mercury lamp-type UV curing machines. The power consumption of the four LED-type point light sources is less than 30 watts when working. Separate linkage control, select the required number of irradiation heads according to needs, the irradiation heads can be controlled individually or linked to meet the requirements of multiple different workstations.

In the past, many traditional high-pressure mercury lamp-type UV point light sources can be completely solved by using one LED-type UV point light source, which greatly reduces the investment of the factory in UV equipment. Stabilize the illumination intensity. Under normal circumstances, the LED will generate heat and increase in temperature after a long time of operation, which will reduce the output illuminance. The UV lamp irradiation head adopts a unique heat treatment system to prevent the LED from decreasing with the increase of temperature, thereby realizing stable UV irradiation. This is very important and environmentally friendly when the irradiation head works for a long time. Unlike other traditional high-pressure mercury lamps, LEDs do not contain mercury. It meets ROHS standards and CE to ensure environmental safety. Simple operation, LCD display, foot switch or panel button control , The control system is convenient to set the irradiation time and power, with an irradiation locking device to ensure the safety of irradiation. The irradiation intensity in the same specification is as high as 8,000mW/cm2. The product is small in size, convenient to operate, easy to install, efficient and energy-saving, and does not affect the environment. At the same time, the unique heat dissipation and temperature control system of the system ensures that the UV irradiation intensity is more stable and reliable.

UV glue produces bubbles during the curing process of its UV curing machine. First, consider whether the volatile content of the UV glue exceeds the standard; second, whether the coating is too thick; third, the temperature during the curing process of 150 ℃ must be too high , It will affect the UV curing reaction. The temperature of UV curing should not be greater than 80°C. Some UV glues can be cured at 150°C for reinforcement heat curing after curing with UV curing machines.

When UV glue passes through the UV curing machine under thick coating and high temperature conditions, it is very easy to produce bubbles. It is not ruled out that the high temperature and UV curing machine can be used as a UVLED curing machine to quickly cure the coating surface, thereby sealing Channels for the volatiles in the primer to overflow, thereby forming bubbles. Therefore, UV-curable coatings do not advocate thick coating. The rapid curing (or partial curing) of the surface layer of the coating seals (or greatly reduces) the overflow channel of the volatile matter in the primer coating, and bubbles are formed. In most cases, when the volatile content in the coating is not very high, these volatiles release the pressure in the form of closed bubbles, leaving the bubbles in the coating forever. When the content of volatile matter in the coating is high and the curing temperature is also high, these bubbles may even be washed by the surface of the coating that has been encrusted, thereby forming open bubbles-pinholes.

Since UV curing machines for UV inks, UV glues, and UV coatings require higher radiation intensity (unit: mJ/cm2), most of the traditional UV curing lamps are high-power high-pressure mercury lamps and photochemical halogen lamps, abbreviated as "Hot light source". The biggest problem in the engineering application of the heat source is that it generates too much heat. If the temperature cannot be effectively controlled, the heat will interfere with the photochemical cross-linking reaction of UV inks, glues and coatings, making it impossible to achieve the desired curing effect. Before 2000, because the UV cold light source of the same wavelength could not provide sufficient UV intensity, the UV curing machine could only meet the needs of engineering applications by strengthening the cold UV curing machine but heat dissipation measures.

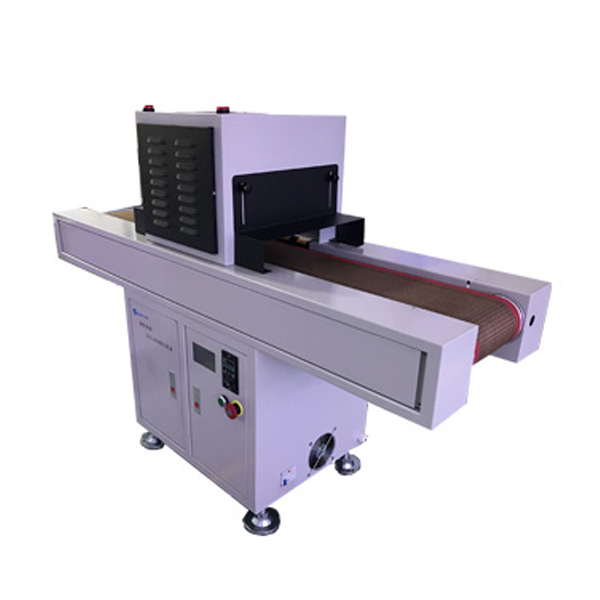

With the increasing maturity of the cold light source technology of the micro-sized LED ultraviolet lamp, the uvled curing machine arranged in a matrix type has gradually reached the luminous intensity of the past hot light source (unit: mJ/cm2), thereby avoiding the heat on the UV curing machine The interference effect. However, there are still some UV curing machines on the market that use a combination of hot light source (high pressure mercury lamp) + cold light source (LED lamp). There is a certain temperature in the early stage of UV curing, which is more conducive to obtaining better UV curing effect. When the product passes through the UV curing machine, the temperature will not exceed 80°C. This may be because some UV inks, glues or coatings with high volatile content need to use heat to remove the volatiles in the early stage of the UV curing reaction.

One of the reasons why the coating of UV curing ink, UV glue or UV coating is not easy to be too thick is that the penetration of UV light is not strong. Too thick coating may cause insufficient curing of the ink, glue or coating on the bottom, resulting in Consequences of insufficient coating hardness, weak adhesion, poor electrical insulation and other poor physical and chemical properties. Therefore, when using UV-curable ink, glue or coating technology, it is necessary to know how to choose materials, but also to know how to choose equipment and operating parameters. Only when the two achieve the best cooperation, can the best effect be obtained.

Shenzhen Height-LED specializes in the production and sales of UVLED point light sources, UVLED line light sources, UVLED surface light sources, UVLED curing machines, UVLED curing ovens, dispensing, spraying, spraying, automation equipment and other products. It has a professional team and rich experience. Won the title of National High-tech Enterprise. Welcome friends in need to come to consult.