First of all, let’s talk about the characteristics of uvled. The uvled ultraviolet cold light source is a device that generates ultraviolet light by a diode light-emitting chip. The light emitted by uvled is relatively single, and has stronger energy in a single waveband, and compared to uvled light source Traditional uv mercury lamps have many advantages, such as cold light sources, because printed matter has more inferior products for printed matter caused by excessive heat, so it is also the main reason why many businesses are chasing uvled printing. Compared with the traditional mercury lamp irradiation, the uvled ultraviolet cold light source has stronger light intensity and longer light time. It can be used for seven or eight years, which can be said to be energy-saving, environmentally friendly and pollution-free.

The two characteristics of ink are as follows:

1. Photoinitiator, solvent ink has no photoinitiator, and the ink film is dried by solvent evaporation; while photo-curable ink relies on the initiator to decompose and generate free radicals to initiate the resin to crosslink and form a hard film. The same series of different colors of inks are based on curing requirements Design and select special photoinitiators and their photoinitiation aids.

2. The solvent is different. The diluting monomer of the light-curable ink participates in the chemical reaction, and its molecular weight is relatively large, so the ability to reduce the viscosity is limited. The solvent of ordinary ink does not participate in the reaction and evaporates 100%, but it can greatly reduce the viscosity of the ink.

3. The influence of pigments. The pigments of ordinary inks hardly affect the drying speed. The inks of different hues are composed of different pigments, the same base material and the same additives. However, the situation of light-cured inks is different. Because different colors selectively absorb and conditionally reflect light of different spectral wavelengths, the curing speeds of inks of different hues are different. For example, all visible light in white is totally reflected and requires higher energy. Although black theoretically absorbs all light, the pigment particles' blocking effect on light prevents the deep curing of the ink, so higher energy is required and the curing speed is slower.

The uvled ultraviolet cold light source is closely related to the ink, and the area irradiated by the uvled and the intensity of the light are closely related to the ink.

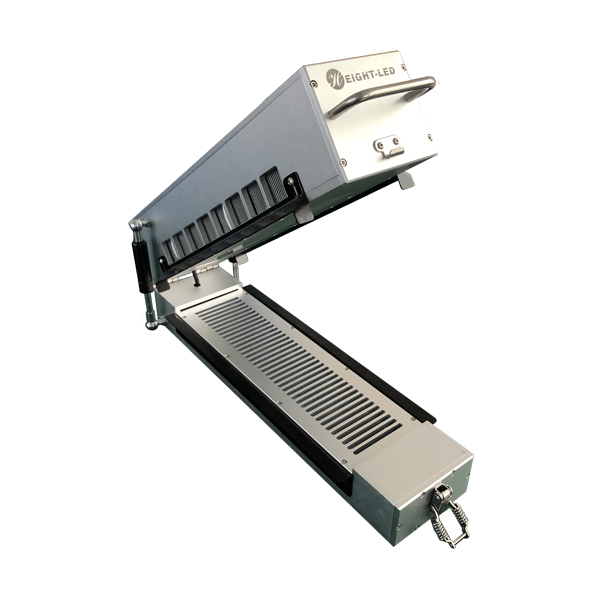

Shenzhen Height-LED specializes in the production of uvled curing equipment, and can customize suitable uvled curing systems for customers. Welcome to consult.