What is the reason for the UVLED curing system to replace the UV mercury lamp in the curing of the printing industry? There are mainly the following reasons:

1. Improve product quality

UV printing has good printability for most substrates. UV prints have clear dots, good tone reproduction, bright and bright ink colors, and high printing consistency. At the same time, since the UVLED curing process is a photochemical reaction process, both the ink layer and the varnish layer have the advantages of strong adhesion, durability, water resistance, chemical corrosion resistance, wear resistance, and aging resistance.

2. Improve production efficiency and economic benefits

Drying by UVLED curing system requires no heat source, no solvent, very short curing time, and most UV processes can achieve a line speed of 400 m/min, which greatly improves production efficiency. After UV ink printing, UV coating is carried out on the machine, and the obtained printed matter has a high gloss and a smooth and uniform surface. After the machine is glazing, the packaging and processing processes such as die-cutting, creasing, gluing and bronzing can be completed immediately, which is very beneficial to the development of high-speed printing. High speed means that storage costs for raw materials, finished products and financial pressure can be reduced. At the same time, due to the low energy consumption of the UVLED curing system, the production cost is greatly reduced.

3. Meet environmental protection requirements

The curing system of UVLED curing system and UV ink is a solvent-free system, that is, a 100% solvent-free formula and no VOC, which just meets today's environmental protection requirements. This is another important feature of UVLED curing. No or little volatile organic compounds are emitted during the curing process, and it will not cause harmful environmental pollution.

4. Fast curing

UV ink will only dry under the irradiation of UVLED curing system. Even if the ink is stored in the ink fountain for a long time, its performance can remain stable, and there will be no skinning on the ink roller. Once irradiated by ultraviolet rays, the ink can be dried instantly, generally only 1/10S can be completely dried and fixed on the surface of the substrate. Traditional thermosetting inks and sheetfed offset printing inks may take several minutes or even days to dry completely. Therefore, using UVLED curing system with UV ink printing has a short delivery time, which is comparable to flexo and gravure printing. Greatly improve the production efficiency of printing.

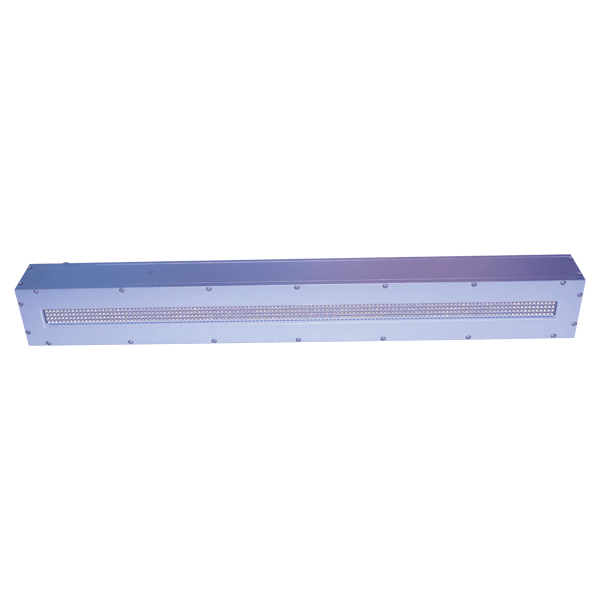

Shenzhen Height-LED specializes in the production and sales of UVLED point light sources, UVLED line light sources, UVLED surface light sources, UVLED curing machines, UVLED curing ovens, dispensing, spraying, spraying, automation equipment and other products, with a professional team and rich experience . We can customize suitable UVLED curing system for customers, welcome to consult.